| Breadboards: BB-34XXXX series |

|

|

Features:

1. Board bases with aluminum plates can stand high frequency and eliminate static interference.

2. Breadboards are made from high quality ABS (3440XX series)

3. Phosphor bronze/ nickel silver spring contact can be operated for more than 10,000 times.

Specifications:

|

Model No. |

Distribution Strips |

Distribution Holes

|

Terminal Strips |

Terminal Holes |

Binding Posts |

Dimensions (mm) |

|

BB-344020 |

2 |

200 |

1 |

640 |

165 x 54.6 x 8.5 | |

|

BB-344040 |

4 |

400 |

2 |

1280 |

3 |

215 x 130 x 9.7 |

|

BB-344060 |

5 |

500 |

3 |

1920 |

4 |

230 x 175 x 9.7 |

|

BB-344080 |

7 |

700 |

4 |

2560 |

4 |

240 x 210 x 9.7 |

What is a breadboard?

A breadboard is used to make up temporary circuits for testing or to try out an idea. No soldering is required so it is easy to change connections and replace components. Parts will not be damaged so they will be available to re-use afterwards. Almost all the Electronics Club projects started life on a breadboard to check that the circuit worked as intended.

A breadboard has many tiny sockets (called 'holes') arranged on a 0.1" grid. The leads of most components can be pushed straight into the holes. ICs are inserted across the central gap with their notch or dot to the left. Wire links can be made with single-core plastic-coated wire of 0.6mm diameter (the standard size). Stranded wire is not suitable because it will crumple when pushed into a hole and it may damage the board if strands break off.

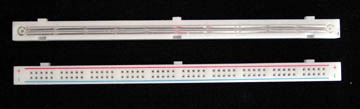

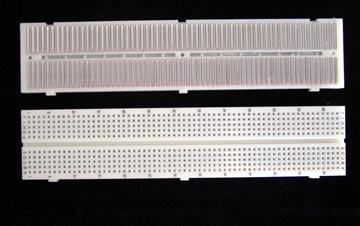

A breadboard usually consists of Distribution Strips (usually 100 tie points in a strip, 50 tie points are linked in a line. Fig. 1) and Terminal Strips ( Usually 630 or 640 tie points in a strip, those tie points are linked in blocks of 5 with no link across the centre Fig. 2)

| Fig. 1 | Fig. 2 |

|

|